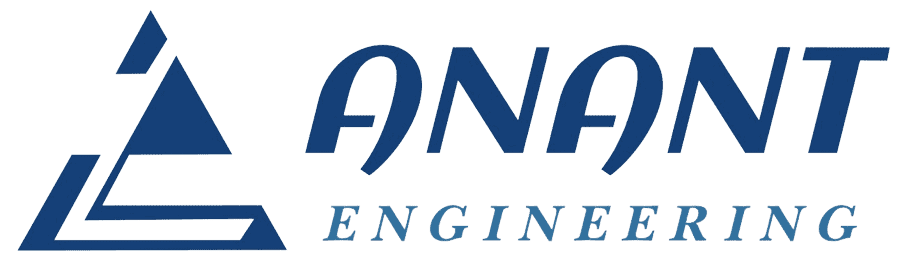

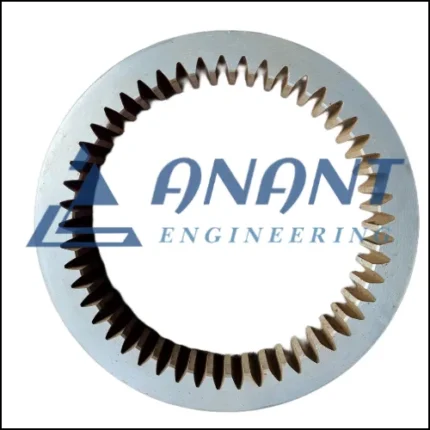

Worm Gear

Welcome to Anant Engineering, the leading manufacturer of worm gears in Mumbai, Maharashtra, India. Our gears which are meticulously designed to deliver unparalleled flexibility and performance in power transmission. With our high-quality products, we ensure a secure and efficient connection between shafts, providing reliable operation and reducing wear and tear.

The Importance of Worm Gears

Worm gears play a crucial role in various industries, including manufacturing, power generation, mining, and more. They enable the transfer of rotational motion and torque between shafts, offering precise control and efficient power transmission. At Anant Engineering, we recognize the significance of gears in keeping industries running smoothly, and our products are engineered to deliver exceptional performance.

Advantages of Our Worm Gears

We offer several advantages that make them a preferred choice for many applications. Firstly, they provide high gear reduction ratios, allowing for efficient torque conversion and speed reduction. Additionally, these gears are highly compact, making them ideal for space-constrained environments. Moreover, their self-locking feature prevents back driving, enhancing safety and stability in applications where holding torque is essential.

Types of Worm Gears Available at Anant Engineering

Anant Engineering offers a variety of gears to suit specific applications. Some common types include:

- Single-Thread Worm Gears: These gears feature a single thread on the worm shaft, providing moderate gear ratios and high torque transmission.

- Multi-Thread Worm Gears: Multi-thread worm gears incorporate multiple threads on the worm shaft, offering higher gear ratios and increased efficiency.

Factors to Consider When Choosing the Right Worm Gear

- Gear Ratio: Determine the required gear ratio to achieve the desired speed reduction or torque multiplication.

- Efficiency: Consider the efficiency of the worm gear system, as it affects power transmission and energy consumption.

- Load Capacity: Evaluate the maximum load capacity that the worm gear can handle to ensure reliable operation under your application’s demands.

- Backlash: Take into account the amount of backlash permissible in your application, as it influences precision and smoothness of motion.

Manufacturing Process of Worm Gears

At Anant Engineering, we employ advanced manufacturing techniques to produce superior worm gears. Our process includes precision machining, heat treatment, and stringent quality control measures to ensure exceptional reliability and durability. We utilize high-quality materials and cutting-edge technology to manufacture the gears that meet or exceed industry standards.

Quality Assurance and Testing

We understand the critical role gears play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our gears undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for load capacity, efficiency, backlash, and durability to ensure that our worm gears meet the highest standards of quality.

Extensive Applications

- Machine Tools

- Packaging Machinery

- Conveyor Systems

- Material Handling Equipment

- Robotics and Automation

- Printing and Paper Machinery

- Food and Beverage Processing

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in