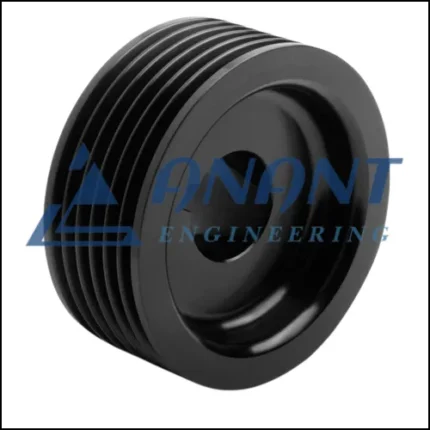

Taper Lock Pulley

Welcome to Anant Engineering, a reputable manufacturer of high-quality taper lock pulleys on based in Mumbai, Maharashtra, India. Our meticulously designed pulleys are engineered to provide unparalleled flexibility and performance in power transmission. With a focus on precision and reliability, our products ensure a secure and the efficient connection between the shaft and the driven components, minimizing slippage and maximizing power transfer.

The Importance of Taper-Lock Pulleys

It plays a crucial role in numerous industries, including manufacturing, power generation, mining, and more. They are essential components that facilitate the transfer of power between the driving and driven components. By utilizing the taper lock bushing system, the taper lock pulleys offer easy installation, removal, and adjustment options, ensuring optimal performance and versatility.

Advantages of Our Taper Bush Pulleys

We offer several advantages that make them a preferred choice for many applications. Firstly, they provide high torque transmission capabilities, allowing for efficient power transfer even in heavy-duty machinery. Additionally, the taper lock bushing system ensures a reliable and secure connection between the pulley and the shaft, reducing the risk of slippage. Moreover, our taper lock pulleys are manufactured with precision, ensuring optimal alignment and smooth operation.

Types of Taper-Lock Pulleys Available at Anant Engineering

We offer a wide range to suit diverse application requirements. Some common types include:

- V-Belt Taper Lock Pulleys: These pulleys are specifically designed to accommodate V-belts, ensuring efficient power transmission and reduced slippage.

- Timing Belt Taper Lock Pulleys: These pulleys are designed for precise timing belt applications, providing accurate synchronization and smooth operation.

Factors to Consider When Choosing the Right Taper Lock Bush Pulley

- Shaft Size and Type: Ensure that the taper lock pulley is compatible with the size and type of shaft you are using.

- Belt Type and Size: Consider the specific belt type and size that the pulley needs to accommodate for optimal performance.

- Speed Ratio: Determine the desired speed ratio between the driving and driven components to achieve the required output speed.

- Load and Power Requirements: Evaluate the load and power requirements of your application to select pulleys that can handle the transmitted power effectively.

Manufacturing Process of Taper-Lock Pulleys

In the manufacturing process of taper-lock pulleys at Anant Engineering, we follow a systematic approach to create high-quality products. Here is an overview of our manufacturing process:

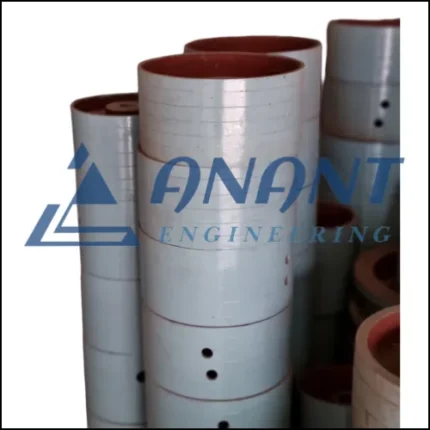

- Material Selection: We begin by carefully selecting the materials for our taper-lock pulleys. Generally, we use high-strength metals such as steel or cast iron that possess excellent mechanical properties and can withstand heavy loads and operating conditions.

- Design and Engineering: Our team of skilled engineers designs the taper-lock pulleys according to customer specifications and industry standards. We consider factors such as torque requirements, belt size compatibility, and application-specific parameters to ensure optimal performance.

- Precision Machining: Once the design is finalized, we move on to the precision machining stage. We utilize advanced CNC (Computer Numerical Control) machines to accurately shape the pulley’s body and grooves. CNC machining allows us to achieve tight tolerances, smooth surfaces, and consistent dimensions, ensuring proper fitment and efficient power transmission.

- Heat Treatment: After machining, the taper-lock pulleys undergo a heat treatment process. Heat treatment enhances the pulley’s mechanical properties, such as hardness and strength, while also relieving internal stresses. This step ensures the pulleys can withstand demanding operating conditions and provide long-lasting performance.

- Surface Finishing: To improve the pulley’s appearance and protect it from corrosion, we apply surface finishes such as painting or powder coating. These coatings not only enhance the aesthetics but also provide an additional layer of protection against environmental factors.

- Quality Control: At Anant Engineering, quality control is an integral part of our manufacturing process. We have a dedicated quality assurance team that performs rigorous inspections and tests at various stages of production. This includes dimensional checks, material analysis, hardness testing, and functional assessments to ensure that every taper-lock pulley meets our strict quality standards.

- Packaging and Delivery: Once the pulleys pass all quality checks, they are carefully packaged to prevent any damage during transportation. We take necessary precautions to ensure secure packaging and efficient delivery to our customers.

By following these steps, we can manufacture taper-lock pulleys that are not only reliable and durable but also ensure efficient power transmission in a wide range of industrial applications. Our commitment to quality and advanced manufacturing techniques sets us apart in delivering superior products to our customers.

Quality Assurance and Testing

We understand the critical role pulleys play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our taper lock pulleys undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for dimensional accuracy, balance, and more to ensure that our pulleys meet the highest standards of quality.

Extensive Applications

- Industrial Machinery and Equipment

- Agricultural Machinery

- Automotive Industry

- Material Handling Equipment

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in