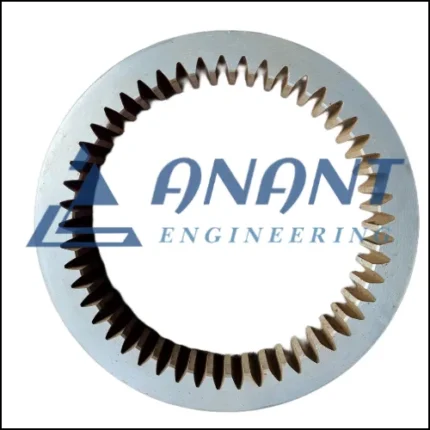

Spur Gear

Welcome to Anant Engineering, a trusted manufacturer of spur gears based in Mumbai, Maharashtra, India. We take pride in producing high-quality gears that offer reliable performance and precise power transmission. We are known as the leading spur gear manufacturers in India, With our commitment to excellence, we ensure that our gear products meet the highest standards of quality, providing a secure and efficient connection between shafts. there are only a few plastic gear manufacturers, and we are counted among the best spur gear manufacturer.

The Importance of Spur Gears

Gears play a fundamental role in various industries, including automotive, manufacturing, robotics, and many more. These gears are designed to transmit power between parallel shafts, enabling efficient torque transfer and motion control. At Anant Engineering, we understand the significance of spur gears in driving industrial processes, and our products are engineered to deliver exceptional performance in diverse applications.

Types of Spur Gears Available at Anant Engineering

Anant Engineering offers a comprehensive range of spur gears to suit different applications. Some common types include:

-

External Gears

-

Internal Gears

-

Custom Spur Gears

-

Plastic Spur Gears

-

Steel Spur Gears

-

Helium Spur Gears

Factors to Consider When Choosing the Right Gear.

When selecting spur gears for your machinery, consider the following factors:

- Pitch Diameter: Determine the pitch diameter of the gear based on the desired gear ratio and shaft spacing to ensure proper meshing and engagement.

- Tooth Configuration: Evaluate the number of teeth, pressure angle, and tooth profile to meet your specific application requirements, such as load capacity, speed, and noise considerations.

- Material Selection: Select the appropriate material for your spur gears based on factors like durability, corrosion resistance, and operating conditions.

- Lubrication: Proper lubrication is crucial for ensuring smooth operation and extending the lifespan of spur gears. Choose the right lubricant and establish a suitable lubrication maintenance schedule.

Manufacturing of Spur Gears at Anant Engineering

At Anant Engineering, we are committed to delivering superior spur gears that excel in reliability, durability, and performance. Our manufacturing process employs advanced techniques, including precision machining, heat treatment, and stringent quality control measures, to ensure the highest level of quality and satisfaction for our customers. By utilizing high-quality materials and cutting-edge technology, we manufacture spur gears that meet and exceed industry standards, providing optimal power transmission solutions for various applications.

- Material Selection:

The manufacturing process begins with the careful selection of high-quality materials suitable for spur gear production. We choose materials based on their mechanical properties, such as strength, hardness, and wear resistance, ensuring that the gears can withstand the demanding operational conditions they will encounter. Common materials used for spur gears include alloy steels, stainless steels, and non-ferrous alloys like bronze or brass.

- Precision Machining:

Precision machining is a crucial step in the production of superior spur gears. Our state-of-the-art machining centers and highly skilled technicians ensure the precise shaping of the gear teeth, bores, and other critical dimensions. Advanced computer numerical control (CNC) technology enables us to achieve tight tolerances and exceptional gear tooth profiles, resulting in gears with smooth and efficient power transmission characteristics.

- Heat Treatment:

To enhance the mechanical properties of the spur gears, they undergo a carefully controlled heat treatment process. Heat treatment involves heating the gears to specific temperatures and then cooling them rapidly or slowly to achieve the desired metallurgical structure. This process improves the gears’ hardness, strength, and toughness, making them more resistant to wear, fatigue, and deformation. The precise control of the heat treatment parameters ensures the gears exhibit excellent mechanical properties and long-lasting performance.

- Finishing Operations:

After precision machining and heat treatment, the spur gears undergo various finishing operations to enhance their surface quality and ensure proper fit and function. These operations may include deburring, polishing, and coating to remove any sharp edges, improve the gear’s aesthetics, and provide additional protection against corrosion.

- Quality Control:

Quality control is an integral part of our manufacturing process. Throughout each stage of production, we conduct rigorous inspections and tests to verify the dimensional accuracy, material integrity, and performance of the spur gears. This includes dimensional checks, hardness testing, gear tooth profile inspections, and non-destructive testing techniques such as magnetic particle or dye penetrant inspection. By adhering to strict quality control measures, we ensure that our spur gears meet the highest standards of reliability and durability.

Advantages of Superior Spur Gears:

- Excellent Power Transmission: Our superior spur gears exhibit precise gear tooth profiles and smooth operation, resulting in efficient power transmission and minimal energy loss. This enhances the overall performance and efficiency of the systems in which they are used.

- Reliable and Durable: The combination of high-quality materials, precise machining, and controlled heat treatment ensures that our spur gears are highly reliable and durable. They can withstand heavy loads, high speeds, and challenging operating conditions, providing long service life and minimizing the need for frequent maintenance or replacements.

- Wide Range of Applications: Spur gears find applications in various industries, including automotive, machinery, robotics, and more. Their versatility allows them to be used in different types of power transmission systems, such as gearboxes, conveyors, and lifting equipment.

- Smooth and Quiet Operation: The precise gear tooth profiles and tight tolerances achieved during manufacturing contribute to smooth and quiet gear operation, minimizing vibration and noise levels. This enhances the overall user experience and reduces the impact on surrounding equipment and operators.

Quality Assurance and Testing

We understand the critical role spur gears play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our spur gears undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for gear tooth profile, dimensional accuracy, load capacity, and durability to ensure that our spur gears meet the highest standards of quality.

Extensive Applications

- Automotive and Transportation

- Manufacturing and Machinery

- Robotics and Automation

- Power Generation

- Medical Equipment

- Aerospace and Defense

- Packaging Machinery

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in