Rack And Pinion Gear

Welcome to Anant Engineering, a premier manufacturer of rack and pinion gears in Mumbai, Maharashtra, India. As a leading manufacturer in the industry, we take pride in delivering top-quality products that are designed to provide unmatched performance and durability. Rack and pinion gears are vital components in many mechanical systems, offering seamless and efficient power transmission. At Anant Engineering, we specialize in designing and manufacturing rack and pinion gears that excel in precision engineering and reliability.

The Importance of Rack & Pinion Gears

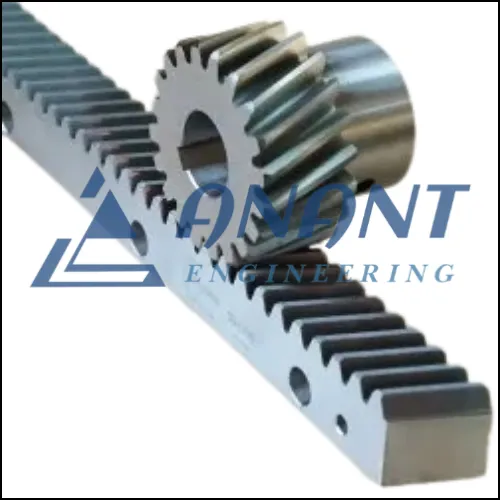

Our rack and pinion gears are meticulously crafted using the finest materials and advanced manufacturing techniques. We understand the crucial role of precision in gear engineering, which is why each of our products undergoes rigorous quality checks at every stage of production. This ensures that every gear we deliver meets the highest standards of accuracy and efficiency.

Advantages of Our Rack & Pinion Gears

One of the key advantages of our rack and pinion gears is their ability to convert rotational motion into linear motion with minimal friction. This makes them an ideal choice for various applications, including steering systems, machine tools, robotics, and more. Whether you require compact gear for a small-scale project or heavy-duty gear for industrial applications, we have the expertise to provide tailored solutions that precisely match your requirements.

Types of Rack & Pinion Gears Available at Anant Engineering

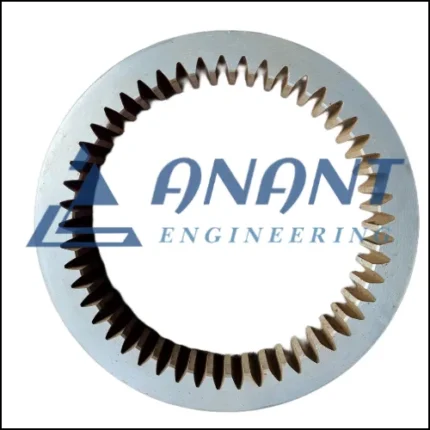

Anant Engineering offers a range of rack and pinion gears to suit specific applications. Some common types include:

Straight Rack and Pinion Gears: These gears have a straight tooth profile and are used when linear motion needs to be converted from rotary motion. They are suitable for applications where precise positioning and high-speed operation are required.

Helical Rack and Pinion Gears: These gears have a helical tooth profile, providing smoother engagement and quieter operation compared to straight rack and pinion gears. They are ideal for applications that demand high accuracy and reduced noise levels.

Factors to Consider When Choosing the Right Rack & Pinion Gear

Pitch and Module: Determine the required pitch and module of the gear system, which defines the tooth size and spacing. This ensures compatibility and efficient power transmission.

Gear Ratio: Calculate the required gear ratio to achieve the desired linear motion or speed reduction.

Load Capacity: Evaluate the maximum load capacity that the rack and pinion gear system can handle to ensure reliable operation under your application’s demands.

Backlash: Consider the desired level of backlash, which is the amount of play between the rack and pinion gears. Lower backlash values result in improved accuracy but may require higher precision manufacturing.

Manufacturing Process of Rack & Pinion Gears

At Anant Engineering, we employ advanced manufacturing techniques to produce superior rack and pinion gears. Our process includes precision machining, heat treatment, and stringent quality control measures to ensure exceptional reliability and durability.

Quality Assurance & Testing

We understand the critical role rack and pinion gears play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our rack and pinion gears undergo rigorous inspection and testing processes to guarantee their performance and reliability. conduct tests for load capacity, tooth engagement, backlash, and durability to ensure that our gears meet the highest standards of quality.

Extensive Applications

- CNC Machinery

- Automation Systems

- Robotics

- Material Handling Equipment

- Industrial Machinery

- Printing and Packaging Machinery

- Medical Equipment

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in