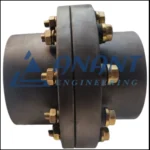

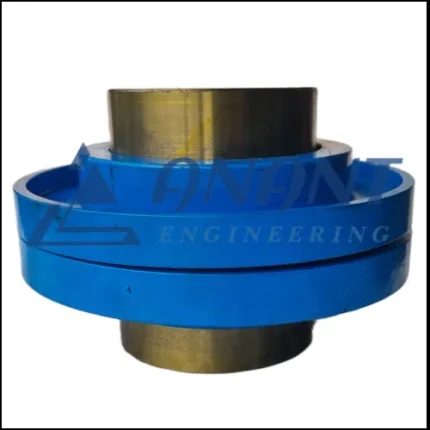

Pin Bush Coupling

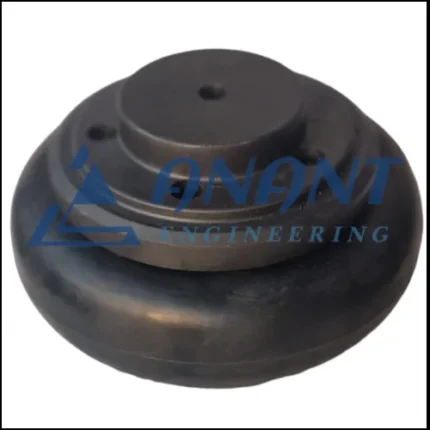

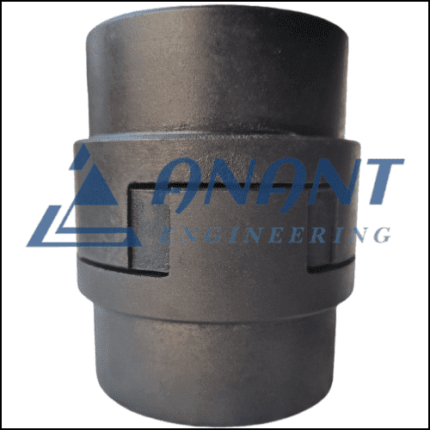

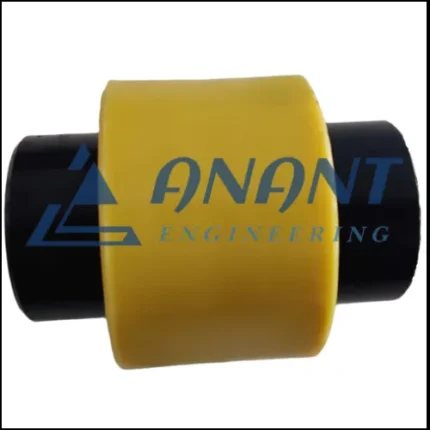

Welcome to Anant Engineering, a leading manufacturer of high-quality pin bush couplings designed to deliver unparalleled flexibility and performance in power transmission. Our meticulously engineered couplings consist of two hubs with crowned teeth on the outside and two outer sleeves with spur teeth on the inside, ensuring a secure and efficient connection between shafts. With their unique design, our pin bush couplings can accommodate angular, parallel, and axial misalignments, minimizing stress on connected machinery and reducing wear and tear.

The Importance of Pin-Bush Couplings

Pin bush couplings play a crucial role in numerous industries, including manufacturing, power generation, mining, and more. They enable the transfer of torque between shafts, compensating for misalignments and reducing the impact of shock loads. This ensures the longevity of machinery, minimizing downtime and maintenance costs. At Anant Engineering, we recognize the significance of pin bush couplings in keeping industries running smoothly, and our products are engineered to deliver exceptional performance.

Advantages of Our Pin-Bush Couplings

Pin bush couplings offer several advantages that make them a preferred choice for many applications. Firstly, they provide high torque transmission capabilities, allowing for efficient power transfer even in heavy-duty machinery. Additionally, they can accommodate angular, parallel, and axial misalignments, enhancing flexibility and reducing stress on connected components. Moreover, their compact design and minimal backlash contribute to smooth operation and increased efficiency.

Types of Pin-Bush Couplings Available at Anant Engineering

At Anant Engineering, we offer a range of pin bush couplings, each suitable for specific applications. Some common types include:

- Sleeve Pin-Bush Couplings: These couplings consist of two flanged sleeves with external teeth that mesh together, transmitting torque between the shafts. They provide reliable and efficient power transmission while accommodating misalignments. Sleeve pin-bush couplings are widely used in various industries, including metal rolling mills, paper machinery, and rubber and plastic industries.

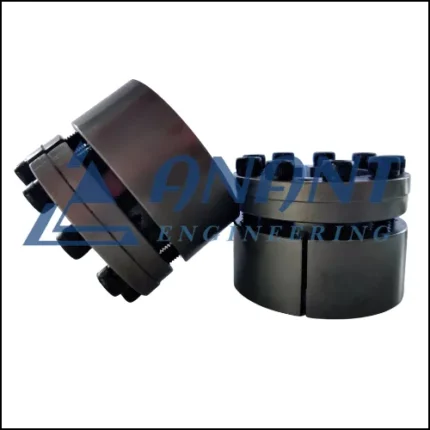

- Spacer Pin-Bush Couplings: Spacer pin-bush couplings incorporate a center spacer to separate the two gear hubs, allowing easy installation and maintenance. They are ideal for applications where frequent disassembly and reassembly are required. Spacer pin-bush couplings find applications in cranes and dredgers, conveyors and elevators, compressors, fans, and blowers.

Factors to Consider When Choosing the Right Pin-Bush Coupling

When selecting pin bush couplings for your machinery, several factors should be considered:

-

- Torque Capacity: Determine the required torque capacity to ensure the pin bush coupling can handle the transmitted power. Consider the torque fluctuations and peak loads that the coupling needs to accommodate.

- Speed and Misalignment: Consider the rotational speed and types of misalignments your application requires the coupling to handle. Evaluate the angular, parallel, and axial misalignment capabilities of the coupling to ensure optimal performance.

- Size and Space Constraints: Evaluate the available space and ensure the chosen pin bush coupling fits within your machinery’s design parameters. Consider the coupling’s dimensions, including hub diameter, length, and overall size.

- Environmental Conditions: Take into account factors such as temperature, moisture, and corrosive environments that may affect the performance and material selection of the pin bush coupling. Choose materials that can withstand the specific environmental conditions of your application.

Manufacturing Process of Pin-Bush Couplings at Anant Engineering

At Anant Engineering, we utilize advanced manufacturing techniques and processes to ensure the production of high-quality pin bush couplings. Our manufacturing process involves several stages, including precision machining, heat treatment, and strict quality control measures.

- Precision Machining: We employ state-of-the-art machinery and equipment to precisely machine the pin bush coupling components. This ensures dimensional accuracy and a smooth surface finish, essential for optimal performance.

- Heat Treatment: The pin bush coupling components undergo a heat treatment process to enhance their mechanical properties, such as hardness and strength. Heat treatment ensures the couplings can withstand the transmitted torque and operational stresses.

- Quality Control: We have a dedicated quality control team that conducts rigorous inspections and tests throughout the manufacturing process. This includes dimensional checks, material analysis, and performance tests to ensure the couplings meet the highest quality standards.

Quality Assurance and Testing

At Anant Engineering, we understand the critical role that pin bush couplings play in industrial applications. We are committed to delivering products of the highest quality, which is why we prioritize comprehensive quality assurance and testing processes. Our rigorous inspection and testing procedures guarantee the performance and reliability of our pin bush couplings, providing our customers with peace of mind.

Torque Capacity Testing

One of the crucial aspects we assess during the testing phase is the torque capacity of our pin bush couplings. We conduct thorough tests to determine the maximum torque that our couplings can handle without experiencing failures or compromising their performance. By subjecting the couplings to different torque levels, we ensure that they can withstand the demands of various applications, including heavy machinery and equipment.

Misalignment Tolerance Evaluation

Misalignment is a common challenge in many industrial settings, and our pin bush couplings are designed to address this issue effectively. We conduct comprehensive misalignment tolerance evaluations to assess how well our couplings can accommodate angular, parallel, and axial misalignments. By simulating different misalignment scenarios, we verify that our couplings can maintain reliable power transmission even in challenging operating conditions.

Durability and Load-Bearing Capacity Assessment

To ensure the long-term durability of our pin bush couplings, we subject them to rigorous durability and load-bearing capacity tests. These tests involve applying repeated loads and stress to the couplings to assess their ability to withstand prolonged and demanding operations. By evaluating the couplings’ performance under these conditions, we guarantee their durability and reliability, minimizing the risk of premature failures and downtime.

Material Analysis and Verification

The materials used in the manufacturing of our pin bush couplings are carefully selected to meet the highest quality standards. We conduct thorough material analysis to verify the composition and properties of the materials, ensuring that they possess the required strength, hardness, and resistance to wear and corrosion. By using high-quality materials, we enhance the overall performance and longevity of our pin bush couplings.

Tight Dimensional Checks

Precision and accuracy are essential when it comes to pin bush couplings. Our quality assurance process includes tight dimensional checks to verify that the couplings meet the specified design parameters. We meticulously measure critical dimensions such as hub diameter, length, and overall size to ensure proper fit and compatibility with various machinery and equipment. This attention to detail ensures that our couplings function optimally within their intended applications.

Compliance with Industry Standards

At Anant Engineering, we are committed to delivering pin bush couplings that meet or exceed industry standards. Our testing processes are designed to align with relevant industry regulations and requirements, ensuring that our products consistently meet the highest quality benchmarks. By adhering to these standards, we provide our customers with reliable and trusted solutions for their power transmission needs.

Continuous Improvement and Innovation

As a leader in the industry, we are dedicated to continuous improvement and innovation. We regularly review and enhance our quality assurance and testing procedures to incorporate the latest advancements in technology and industry best practices. This commitment allows us to stay at the forefront of the industry, delivering cutting-edge pin bush couplings that surpass customer expectations.

Extensive Applications of Pin Bush Couplings

Pin bush couplings find extensive applications in various industries, including:

- Metal Rolling Mills: Pin bush couplings are used in rolling mills to transmit torque between different rolling mill components, ensuring smooth and efficient metal shaping processes.

- Paper Machinery: Pin bush couplings facilitate power transmission in paper machinery, enabling the smooth operation of various components such as rollers, cutters, and feeders.

- Cranes and Dredgers: Pin bush couplings are utilized in cranes and dredgers to transfer torque between different mechanisms, ensuring precise and reliable lifting and dredging operations.

- Rubber and Plastic Industries: Pin bush couplings play a vital role in rubber and plastic industries, enabling efficient power transmission in extruders, mixers, and other machinery.

- Cement Plants: Pin bush couplings are employed in cement plants to transfer torque between different equipment, such as crushers, mills, and kilns, ensuring continuous and efficient cement production.

- Conveyors and Elevators: Pin and bush couplings are used in conveyor systems and elevators to transmit torque between the drive unit and the conveying mechanism, enabling the smooth and reliable movement of materials.

- Compressors, Fans, and Blowers: Pin bush couplings provide dependable power transmission in compressors, fans, and blowers, contributing to efficient air and gas handling processes.

Anant Engineering can be your trusted partner for high-quality pin bush couplings designed to deliver exceptional performance and flexibility in power transmission. With our meticulous engineering, advanced manufacturing techniques, and stringent quality control measures, we provide couplings that can accommodate misalignments, minimize stress on machinery, and ensure smooth and efficient operation.

Whether you require pin bush couplings for metal rolling mills, paper machinery, cranes, dredgers, rubber and plastic industries, cement plants, conveyors, elevators, or compressors, fans, and blowers, we have the perfect solution for your needs.

Contact our experienced team today to discuss your specific requirements and discover how our pin bush couplings can enhance the performance and reliability of your machinery. Choose Anant Engineering for reliable and top-quality pin bush couplings that ensure efficient and flexible power transmission in your industrial applications.

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in