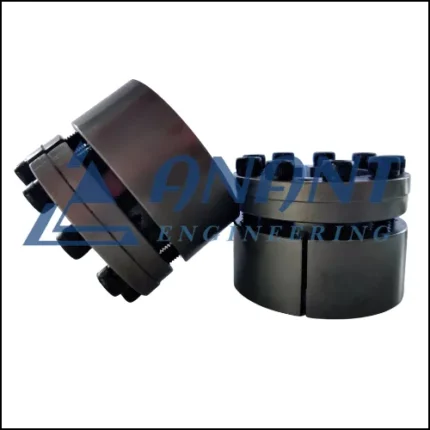

Nylon Sleeve coupling

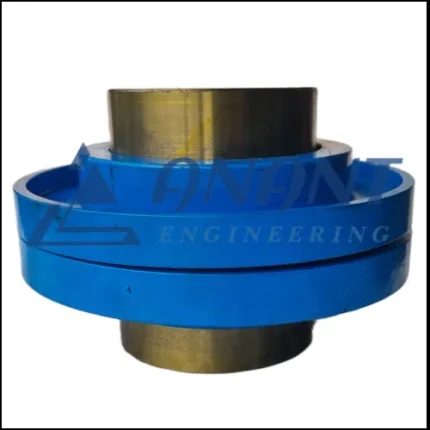

Anant Engineering’s nylon sleeve couplings are meticulously designed to provide unparalleled flexibility and performance in power transmission. Our couplings features, a coupling that acts as a flexible element between two hubs, ensuring a secure and efficient connection between shafts. This unique design allows our nylon sleeve couplings to accommodate angular, parallel, and axial misalignments, minimizing stress on connected machinery and reducing wear and tear.

The Importance of Nylon Sleeve Coupling

These couplings play a crucial role in numerous industries, including manufacturing, power generation, mining, and more. They enable the transfer of torque between shafts while compensating for misalignments and reducing the impact of shock loads. This ensures the longevity of machinery, minimizing downtime and maintenance costs. At Anant Engineering, we recognize the significance of coupling in keeping industries running smoothly, and our products are engineered to deliver exceptional performance.

Advantages of Our Nylon Sleeve Coupling

These couplings offer several advantages that make them a preferred choice for many applications. Firstly, they provide high torque transmission capabilities, allowing for efficient power transfer even in heavy-duty machinery. Additionally, they can accommodate angular, parallel, and axial misalignments, enhancing flexibility and reducing stress on connected components. Moreover, their lightweight construction and excellent damping characteristics contribute to smooth operation and increased efficiency.

Types of Nylon Sleeve Couplings Available at Anant Engineering

At Anant Engineering, we offer a range of couplings, each suitable for specific applications. Some common types include:

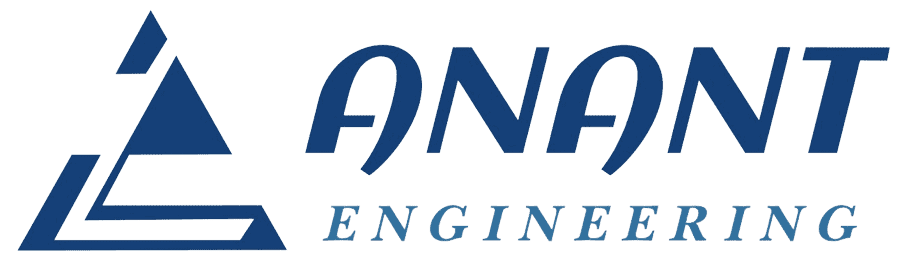

1. Straight Nylon Sleeve Couplings: These couplings feature a straight sleeve that connects two hubs, providing flexibility and torque transmission.

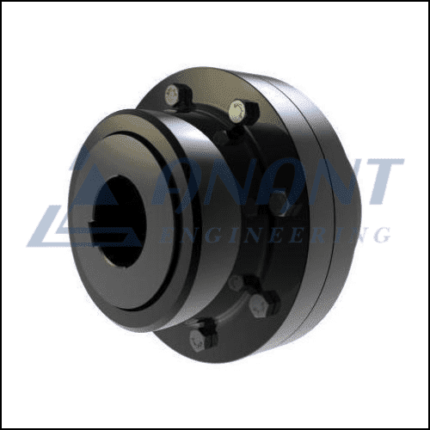

2. Taper Bushed Nylon Sleeve Couplings: These couplings incorporate a tapered bushing mechanism, allowing for easy installation and maintenance while providing excellent torque transmission capabilities.

Factors to Consider When Choosing the Right Nylon Sleeve Coupling

When selecting These couplings for your machinery, several factors should be considered:

- Torque Capacity: Determine the required torque capacity to ensure that it can handle the transmitted power.

- Speed and Misalignment: Consider the rotational speed and types of misalignments your application requires the coupling to handle.

- Size and Space Constraints: Evaluate the available space and ensure the chosen coupling that fits within your machinery’s design parameters.

- Environmental Conditions: Take into account factors such as temperature, moisture, and corrosive environments that may affect the performance and material selection of the nylon sleeve coupling.

Manufacturing Process of Nylon Sleeve Coupling at Anant Engineering

At Anant Engineering, we employ advanced manufacturing techniques to produce superior nylon sleeve couplings. Our process includes precision machining, quality control measures, and the use of high-quality materials to ensure exceptional reliability and durability. We utilize cutting-edge technology to manufacture of these couplings that meet or exceed industry standards.

Quality Assurance and Testing

We understand the critical role nylon sleeve couplings play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our nylon sleeve couplings undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for torque capacity, misalignment tolerance, and durability to ensure that our nylon sleeve couplings meet the highest standards of quality.

Extensive Applications of Nylon Sleeve Coupling

TO find extensive applications in various industries, including:

- Metal Rolling Mills

- Paper Machinery

- Cranes and Dredgers

- Rubber and Plastic Industries

- Cement Plants

- Conveyors and Elevators

- Compressors, Fans, and Blowers

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in