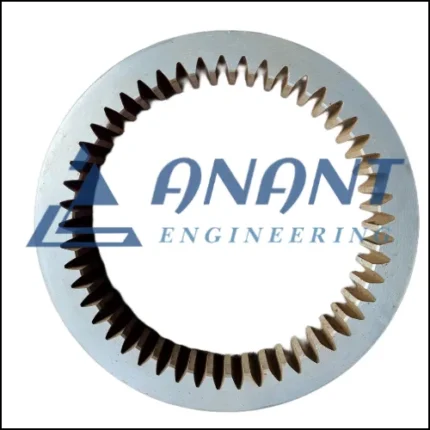

Helical Gear

Welcome to Anant Engineering, the leading manufacturer of helical gears in Mumbai, Maharashtra, India. With our dedication to excellence, we provide high-quality gears that offer unmatched flexibility and performance in power transmission. As a trusted manufacturer, we prioritize delivering reliable operation and reducing wear and tear through our meticulously designed gear couplings.

The Importance of Helical Gears

These gears are indispensable components in various industries, including manufacturing, automotive, aerospace, and more. These gears excel in transmitting torque between parallel or intersecting shafts, ensuring smooth and efficient power transmission. At Anant Engineering, we recognize the significance of these gears in maintaining optimal functionality across industries, and our products are engineered to deliver exceptional performance.

Advantages of Anant Engineering’s Helical Gears

Our gears provide several advantages that make them a preferred choice for numerous applications. First and foremost, they offer improved load-carrying capacity, enabling efficient power transfer even in heavy-duty machinery. The helical tooth geometry promotes smooth and quiet operation, minimizing vibrations and noise levels. Additionally, it exhibits higher efficiency than other gear types, resulting in reduced energy consumption.

Types of Helical Gears Available at Anant Engineering

We offer a wide range to suit specific applications. Some common types include:

- Parallel Helical Gears: These gears have parallel-aligned axes and provide excellent power transmission efficiency and load-carrying capacity. They are suitable for applications requiring high torque and speed control.

- Double Helical Gears (Herringbone Gears): These gears feature two sets of helical teeth with opposite helix angles. The double helix design eliminates axial thrust and ensures balanced transmission, making them ideal for applications with high-speed and heavy-load requirements.

Factors to Consider When Choosing the Right Helical Gear

- Gear Ratio: Determine the required gear ratio to achieve the desired speed reduction or torque multiplication for your specific application.

- Tooth Configuration: Evaluate the helix angle, number of teeth, and tooth profile to ensure compatibility with your system requirements, such as load, speed, and noise considerations.

- Load Capacity: Assess the maximum load capacity that it can handle to ensure reliable and safe operation under your application’s demands.

- Efficiency: Consider the efficiency of the helical gear system, as it affects power transmission and energy consumption. these gears are known for their high efficiency compared to other gear types.

Manufacturing Process of Helical Gears at Anant Engineering

At Anant Engineering, we employ advanced manufacturing techniques to produce superior helical gears. Our process involves precision machining, heat treatment, and rigorous quality control measures to ensure exceptional reliability and durability. We utilize high-quality materials and cutting-edge technology to manufacture gears that meet or exceed industry standards.

Quality Assurance and Testing

We understand the critical role of gears play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our helical gears undergo stringent inspection and testing processes to guarantee their performance and reliability. We conduct tests for load capacity, tooth engagement, and durability to ensure that our gears meet the highest standards of quality.

Extensive Applications

- Automotive and Transportation

- Aerospace and Defense

- Heavy Machinery and Equipment

- Oil and Gas

- Marine and Shipbuilding

- Agricultural Machinery

- Material Handling Equipment

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in