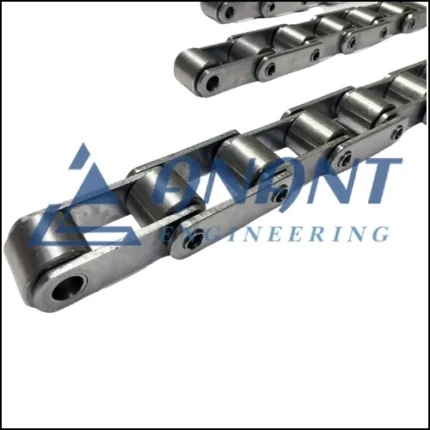

Conveyor Rollers

Welcome to Anant Engineering, a leading manufacturer of rollers located in Mumbai, Maharashtra, India. Our meticulously designed conveyor rollers are engineered to deliver unparalleled flexibility and performance in material handling applications. With a focus on quality and reliability, our products ensure efficient and reliable operation of conveyor systems in industries worldwide.

The Importance of Conveyor Rollers

It plays a crucial role in the smooth and efficient movement of conveyor belts, facilitating the transportation of materials across different stages of production. They are vital components in industries such as mining, manufacturing, logistics, and more. these rollers support and guide the belt, ensuring proper alignment and reducing friction. At Anant Engineering, we understand the significance of conveyor rollers in maintaining optimal conveyor system performance, and our products are designed to meet the highest standards.

Advantages of Our Conveyor Rollers

Our rollers offer several advantages that make them a preferred choice for various applications. Firstly, they provide exceptional durability and longevity, ensuring prolonged service life with minimal maintenance requirements. Additionally, our rollers are designed to minimize noise, vibration, and energy consumption, contributing to a safer and more cost-effective operation. Moreover, our rollers are engineered for smooth and reliable material handling, reducing the risk of belt damage and improving overall system efficiency.

Types of Conveyor Rollers Available at Anant Engineering

We offer a wide range to meet diverse application requirements. Some common types include:

- Gravity Rollers: These rollers are designed for gravity-fed conveyor systems, allowing materials to move under their own weight.

- Powered Rollers: Powered rollers are driven by motors and are ideal for conveyors requiring powered assistance for material movement.

- Tapered Rollers: Tapered rollers are used to facilitate the smooth transition of products from one conveyor to another or for curve applications.

Factors to Consider When Choosing Conveyor Rollers

When selecting conveyor rollers for your material handling system, several factors should be considered:

- Load Capacity: Determine the weight and size of the materials being conveyed to ensure the rollers can handle the load.

- Roller Diameter and Length: Consider the required roller diameter and length to achieve proper belt support and minimize friction.

- Roller Material: Evaluate the material compatibility with the conveyed products and the operating conditions, such as temperature and moisture.

- Bearing Type: Choose the appropriate bearing type based on the application requirements, such as precision bearings for high-speed applications.

Manufacturing Process of Conveyor Rollers

At Anant Engineering, we employ advanced manufacturing techniques to produce superior conveyor rollers. Our process includes precision machining, balanced design, and stringent quality control measures to ensure exceptional reliability and performance. We utilize high-quality materials and cutting-edge technology to manufacture rollers that meet or exceed industry standards.

Quality Assurance and Testing

Quality assurance and testing are integral to our manufacturing process. At Anant Engineering, our conveyor rollers undergo rigorous inspection and testing to guarantee their performance and reliability. We conduct tests for load capacity, dimensional accuracy, and durability to ensure that our rollers meet the highest standards of quality.

Extensive Applications

-

- Logistics and Warehousing

- Mining and Quarrying

- Manufacturing and Assembly

- Food Processing

- Packaging and Distribution Centers

- Automotive and Transportation

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in