Conveyor Pulley

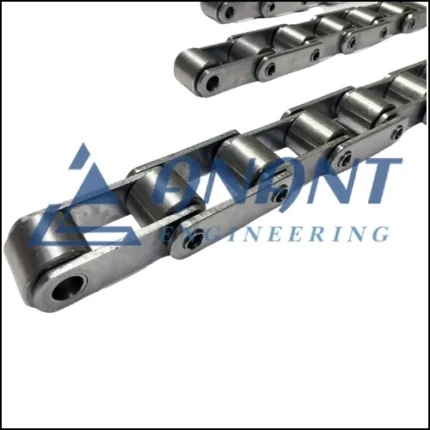

Welcome to Anant Engineering, a renowned manufacturer of conveyor pulleys located in Mumbai, Maharashtra, India. Our meticulously designed conveyor pulleys are engineered to deliver unparalleled flexibility and performance in various material handling applications. With a focus on quality and reliability, our products ensure efficient and reliable operation of conveyor systems in industries worldwide.

The Importance of Conveyor Pulleys

It plays a crucial role in the smooth and efficient movement of conveyor belts, enabling the transportation of materials across different stages of production. They are essential components in industries such as mining, construction, manufacturing, and more. pulleys facilitate the redirection and tensioning of the belt, ensuring proper alignment and minimizing the risk of belt slippage. At Anant Engineering, we understand the significance of pulleys in maintaining optimal conveyor system performance, and our products are designed to meet the highest standards.

Advantages of Our Conveyor Pulleys

We offer several advantages that make them a preferred choice for various applications. Firstly, they provide exceptional reliability and durability, ensuring prolonged service life with minimal maintenance requirements. Additionally, our pulleys are designed to effectively manage the tension and tracking of conveyor belts, reducing the risk of belt damage and improving overall system efficiency. Moreover, our pulleys are engineered to minimize noise, vibration, and energy consumption, contributing to a safer and more cost-effective operation.

Types of Conveyor Pulleys Available at Anant Engineering

We offer a range to meet diverse application requirements. Some common types include:

- Drive Pulleys: These pulleys are located at the discharge end of the conveyor and are responsible for transmitting power to the belt, enabling its movement.

- Head Pulleys: Positioned at the head of the conveyor, these pulleys redirect the belt and assist in the removal of material from the system.

- Tail Pulleys: Situated at the tail end of the conveyor, these pulleys provide tension to the belt and facilitate its return.

Factors to Consider When Choosing Conveyor Pulleys

- Belt Type and Size: Ensure that the pulleys are compatible with the specific belt type and size used in your conveyor system.

- Shaft Diameter and Length: Consider the required shaft diameter and length to achieve proper belt tension and ensure a secure connection.

- Pulley Design and Construction: Evaluate factors such as pulley diameter, face width, and hub configuration based on the application requirements and load capacity.

- Material Selection: Take into account the operating conditions, such as temperature, moisture, and the characteristics of the conveyed material, to choose the most suitable material for the pulleys.

Manufacturing Process of Conveyor Pulleys

At Anant Engineering, we employ advanced manufacturing techniques to produce superior conveyor pulleys. Our process includes precision machining, balanced design, and stringent quality control measures to ensure exceptional reliability and performance. We utilize high-quality materials and cutting-edge technology to manufacture pulleys that meet or exceed industry standards.

Quality Assurance and Testing

Quality assurance and testing are integral to our manufacturing process. At Anant Engineering, our conveyor pulleys undergo rigorous inspection and testing to guarantee their performance and reliability. We conduct tests for balance, run-out, and load capacity to ensure that our pulleys meet the highest standards of quality.

Extensive Applications

Anant Engineering’s conveyor pulleys find extensive applications in various industries, including:

- Mining and Quarrying

- Cement and Aggregate Plants

- Steel and Metal Industries

- Ports and Terminals

- Food Processing

- Packaging and Distribution Centers

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in