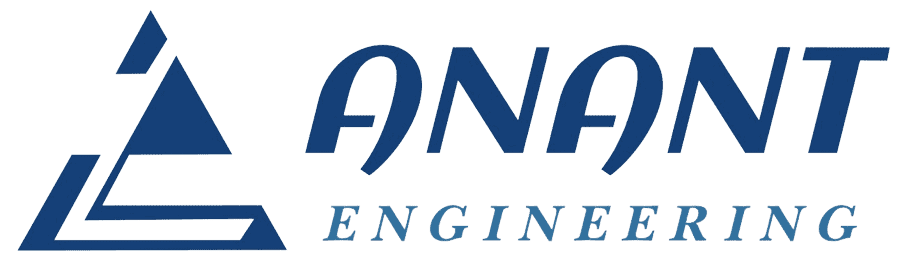

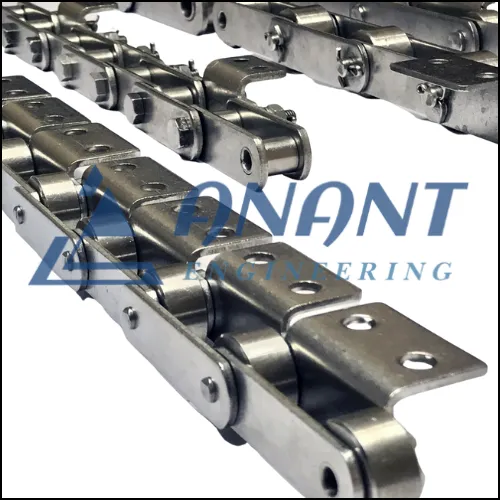

Conveyor Chain

Welcome to Anant Engineering, a renowned manufacturer of conveyor chains based in Mumbai, Maharashtra, India. Our meticulously designed conveyor chains are engineered to provide unparalleled flexibility and performance in material handling applications. With our high-quality products, we ensure a secure and efficient movement of goods and materials, meeting the diverse needs of various industries.

The Importance of Conveyor Chains

It plays a crucial role in a wide range of industries, including manufacturing, mining, logistics, and more. They enable the continuous and efficient movement of materials along conveyor systems, ensuring smooth operations and optimized productivity. At Anant Engineering, we understand the significance of the chains in maintaining the flow of goods and materials, and our products are designed to deliver exceptional performance and reliability.

Advantages of Our Conveyor Chains

We offer several advantages that make them a preferred choice for many applications. Firstly, they provide high tensile strength and load-carrying capacity, allowing for the efficient movement of materials, even in demanding environments. Additionally, our chains are designed to withstand harsh operating conditions, including high temperatures, abrasive materials, and corrosive environments. Moreover, their precise construction and uniform pitch contribute to smooth and reliable operation, reducing downtime and optimizing productivity.

Types of Conveyor Chains Available at Anant Engineering

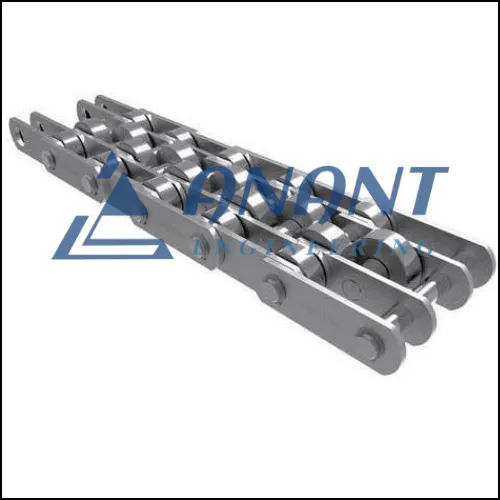

We offer a wide range to suit various applications. Some common types include:

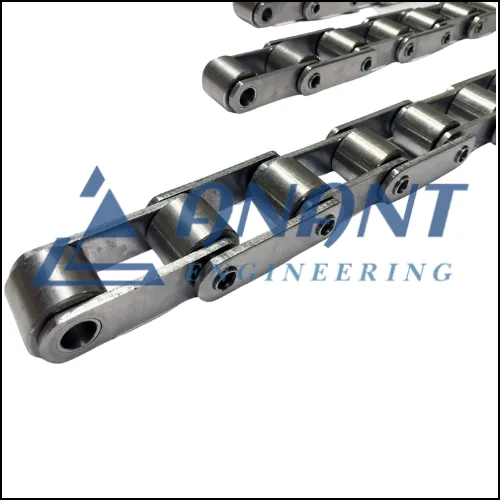

- Roller Conveyor Chains: These chains feature rollers that facilitate the smooth movement of materials on a conveyor, suitable for applications with medium to heavy loads.

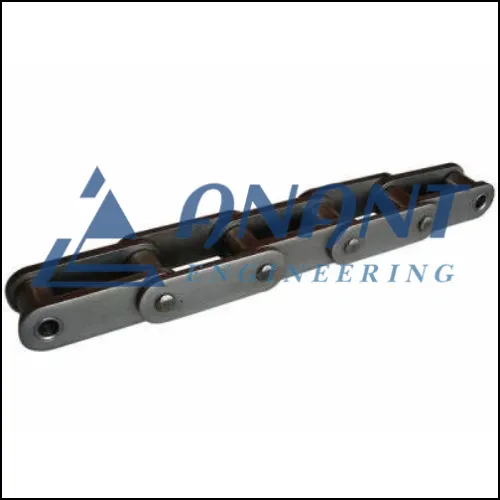

- Flat-Top Conveyor Chains: Designed with flat plates, these chains are ideal for conveying products with a flat base or in applications where stability is crucial.

- Pallet Conveyor Chains: These chains are specifically designed for conveying palletized loads, ensuring secure and efficient movement within warehouses and distribution centers.

Factors to Consider When Choosing Conveyor Chains

When selecting conveyor chains for your material handling systems, several factors should be considered:

- Tensile Strength and Load Capacity: Determine the required tensile strength and load-carrying capacity based on the weight and nature of the materials being conveyed.

- Pitch Size and Roller Diameter: Select the appropriate pitch size and roller diameter to ensure compatibility with your conveyor system and smooth material flow.

- Lubrication Requirements: Consider the lubrication requirements of your chains and choose the appropriate lubrication method to ensure optimal performance and extended chain life.

- Environmental Conditions: Take into account factors such as temperature variations, moisture, and exposure to chemicals or abrasive materials that may impact the material selection and performance of the chains.

Manufacturing Process of Conveyor Chains

At Anant Engineering, we utilize advanced manufacturing techniques to produce superior conveyor chains. Our process includes precision machining, heat treatment, and stringent quality control measures to ensure exceptional reliability and durability. We employ high-quality materials and cutting-edge technology to manufacture chains that meet or exceed industry standards.

Quality Assurance and Testing

Quality assurance and testing are integral to our manufacturing process. At Anant Engineering, our conveyor chains undergo rigorous inspection and testing to guarantee their performance and reliability. We conduct tests for tensile strength, wear resistance, and overall durability to ensure that our chains meet the highest standards of quality.

Extensive Applications

- Manufacturing and Assembly Lines

- Warehousing and Distribution

- Mining and Quarrying

- Food Processing and Packaging

- Automotive and Transportation

- Pharmaceutical and Chemical Industries

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in