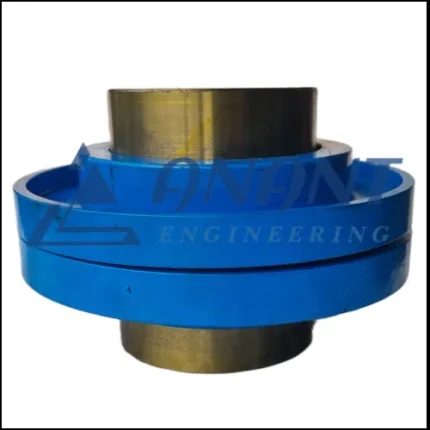

Brake Drum Coupling

Welcome to Anant Engineering, a leading manufacturer of brake drum couplings located in Mumbai, Maharashtra, India. We specialize in producing high-quality brake drum couplings that offer reliable performance and efficient power transmission. With our commitment to excellence, we ensure that our couplings meet the highest standards of quality, providing a secure and effective connection in various applications.

The Importance of Brake Drum Couplings

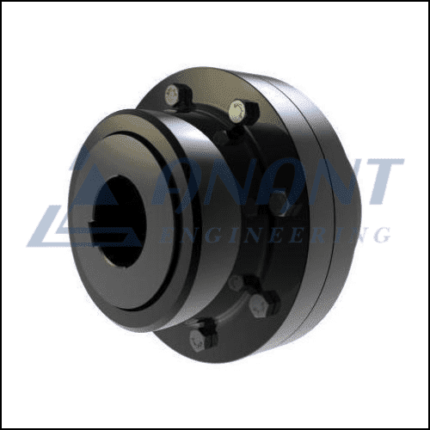

Brake drum couplings play a crucial role in transmitting torque between two shafts, compensating for misalignments and providing flexibility. These couplings are widely used in industries such as manufacturing, material handling, and heavy machinery, where reliable power transmission and shaft protection are essential. At Anant Engineering, we understand the significance of brake drum couplings in ensuring smooth operation and minimizing downtime, and our products are engineered to deliver exceptional performance in demanding conditions.

Advantages of Anant Engineering’s Brake Drum Couplings

Our couplings offer several advantages that make them a preferred choice for numerous applications. Firstly, they provide high torque transmission capabilities, enabling efficient power transfer even in heavy-duty machinery. Additionally, couplings accommodate angular, parallel, and axial misalignments, ensuring reliable operation and reducing stress on connected equipment.

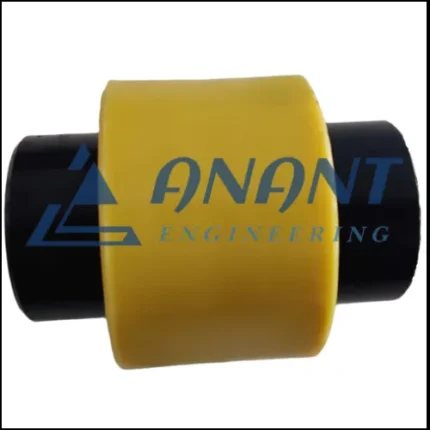

Types of Brake Drum Couplings Available at Anant Engineering

- Flexible Brake Drum Couplings: These couplings provide flexibility and accommodate misalignments while transmitting torque efficiently. They are suitable for applications that require compensation for angular and parallel misalignments.

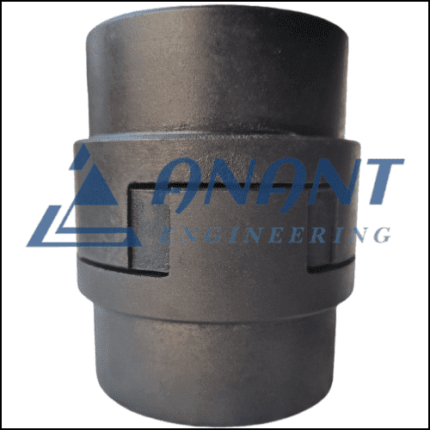

- Rigid Brake Drum Couplings: These couplings provide a rigid connection between shafts, offering precise torque transmission and minimal backlash. They are ideal for applications with minimal misalignments and high torque requirements.

Factors to Consider When Choosing the Right Brake Drum Coupling

When selecting couplings for your machinery, consider the following factors:

- Torque Requirements: Determine the torque capacity needed for your application to ensure efficient power transmission and avoid coupling failure.

- Misalignment Compensation: Evaluate the level of misalignment your system may experience, such as angular, parallel, or axial misalignments, and choose a coupling that can effectively compensate for them.

- Space Limitations: Consider the available space for installation to ensure the selected brake drum coupling fits within the system constraints.

- Environmental Conditions: Assess the operating environment, including temperature, humidity, and exposure to chemicals or contaminants, and choose a coupling that can withstand these conditions.

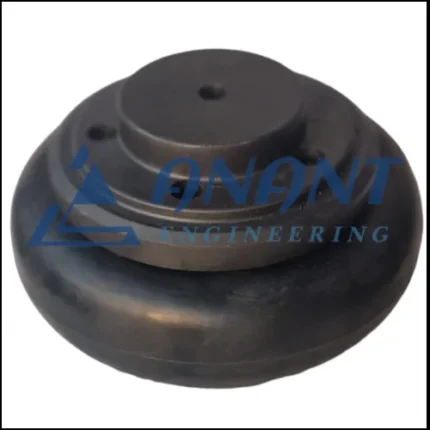

Manufacturing Process of Brake Drum Couplings at Anant Engineering

At Anant Engineering, we employ advanced manufacturing techniques to produce superior brake drum couplings. Our process includes precision machining, quality material selection, and stringent quality control measures to ensure exceptional reliability and durability. We utilize high-quality materials and cutting-edge technology to manufacture couplings that meet or exceed industry standards.

Quality Assurance and Testing

We understand the critical role that couplings play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our couplings undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for torque capacity, misalignment compensation, and durability to ensure that our couplings meet the highest standards of quality.

Extensive Applications

- Steel Mills and Foundries

- Material Handling Equipment

- Mining and Quarrying

- Paper and Pulp Industries

- Chemical and Petrochemical Plants

- Power Generation Facilities

- Construction Machinery

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in