Locking Assembly Coupling Manufacturer in Surat

Locking Assembly Coupling Manufacturer in Surat

Introduction

Locking Assembly Coupling Manufacturer in Surat– Anant Engineering

In the world of industrial machinery, few components are as critical as jaw couplings. They play a pivotal role in ensuring efficient power transmission while reducing wear and tear on machinery. If you're in need of high-quality jaw couplings, look no further than Anant Engineering, a trusted Locking Assembly Coupling Manufacturer in Surat. In this article, we’ll delve into why locking assembly are so essential and why Anant Engineering is the preferred choice for businesses across various industries.

About Anant Engineering

Anant Engineering is a prominent player in the mechanical engineering sector, with a special focus on manufacturing reliable and efficient Locking Assembly couplings. Established with a vision to provide customized and high-performing industrial solutions, they have carved out a niche for themselves in India's thriving industrial hub. Over the years, Anant Engineering has earned the trust of numerous clients by consistently delivering top-tier products tailored to their needs.

What Are Locking Assembly ?

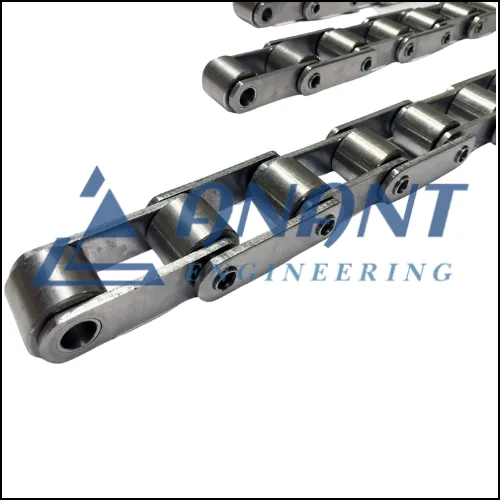

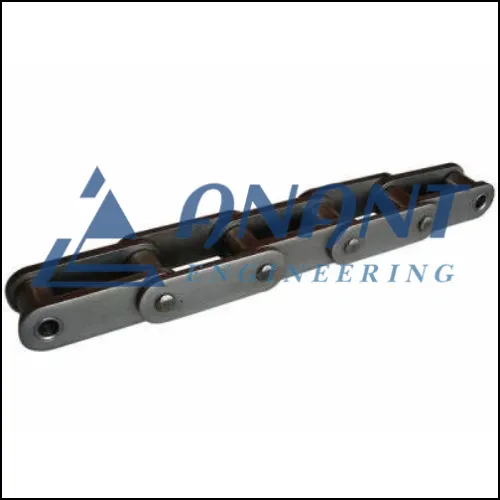

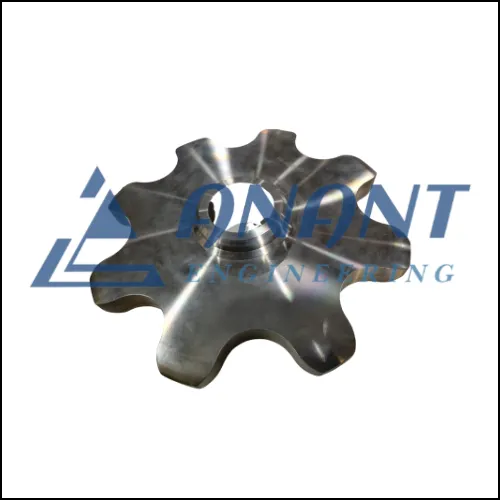

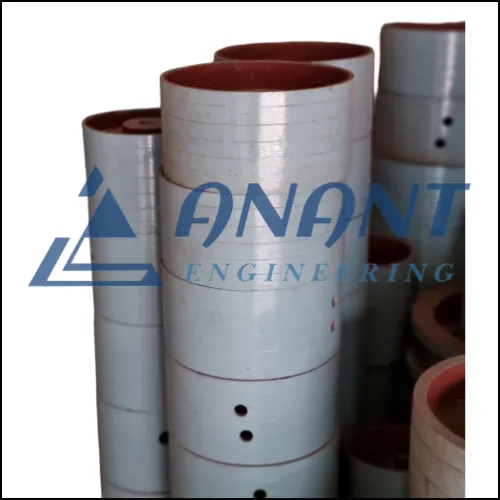

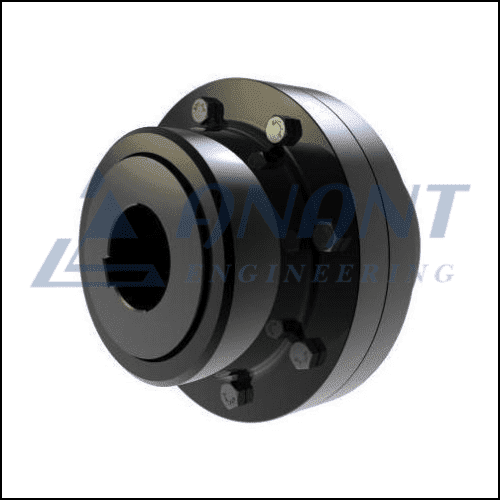

Locking Assembly couplings are mechanical devices used to connect two shafts and transmit torque between them. Their unique design, featuring two hubs and an elastomeric spider insert, allows for flexible movement and vibration absorption, making them ideal for various industrial applications. By providing a buffer between shafts, jaw couplings prevent unnecessary stress and wear on equipment, extending machinery life.

Types of Locking Assembly Couplings

There are several types of Locking Assembly couplings available, each serving different industrial needs:

- Spacer Locking Assembly Couplings: These couplings are designed for applications where space constraints exist and can accommodate larger misalignments between shafts.

- Torsional Locking Assembly Couplings: Primarily used in applications requiring better control over torsional vibrations and damping.

Applications of Locking Assembly Couplings

Locking Assembly couplings are used across multiple industries, including:

- Automotive Industry: They are essential for smooth power transmission in vehicles, helping reduce vibrations and enhancing efficiency.

- Manufacturing Sector: Factories and production lines depend on jaw couplings to maintain consistent machinery operation with minimal downtime.

- Power Transmission Systems: Jaw couplings are ideal for transmitting torque in power plants, ensuring minimal energy loss.

Advantages of Locking Assembly Couplings

Opting for Locking Assembly couplings in your industrial setup brings a host of benefits:

- Durability and Reliability: Locking Assembly couplings are designed to withstand high levels of stress and torque while maintaining optimal performance.

- Vibration Damping: The elastomer insert effectively dampens vibrations, protecting sensitive machinery components from damage.

- Easy Maintenance: Locking Assembly couplings are known for their straightforward design, making them easy to install, inspect, and maintain.

Customization Options at Anant Engineering

At Anant Engineering, every client is treated as a unique partner. Their team understands that no two industries or machines have the same requirements, so they offer fully customizable Locking Assembly couplings. From size and material to performance characteristics, Anant Engineering works closely with clients to design solutions that perfectly fit their needs.

Why Choose Anant Engineering?

There are many reasons why Anant Engineering should be your go-to manufacturer for Locking Assembly couplings:

- Quality Assurance: Anant Engineering adheres to stringent quality control processes to ensure that every coupling meets high standards of durability and performance.

- Customer-Centric Approach: With a focus on understanding the unique requirements of every client, Anant Engineering provides tailored solutions and excellent after-sales support.

How to Maintain Jaw Couplings

To maximize the lifespan and effectiveness of your jaw couplings, follow these maintenance tips:

- Routine Inspections: Regularly check the elastomer inserts for signs of wear or damage.

- Proper Lubrication: Ensure that all moving parts are well-lubricated to prevent friction and overheating.

- Alignment Monitoring: Misalignment can cause excessive wear, so it's important to regularly check and realign shafts as needed.

Client Testimonials and Success Stories

Over the years, Anant Engineering has built strong relationships with clients across various industries, including automotive, manufacturing, and power transmission. Satisfied customers have praised their ability to deliver high-quality, customized products on time, helping businesses reduce maintenance costs and improve machinery performance.

Conclusion

In conclusion, jaw couplings are vital for ensuring smooth, efficient, and durable operation of industrial machinery. If you're looking for a reliable Locking Assembly Coupling Manufacturer in Surat, Anant Engineering stands out for their quality products, customization options, and customer-first approach. Whether you need a standard coupling or a tailor-made solution, Anant Engineering is well-equipped to meet your needs.