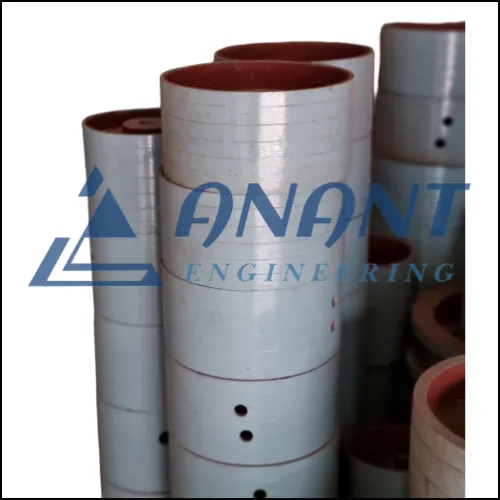

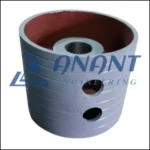

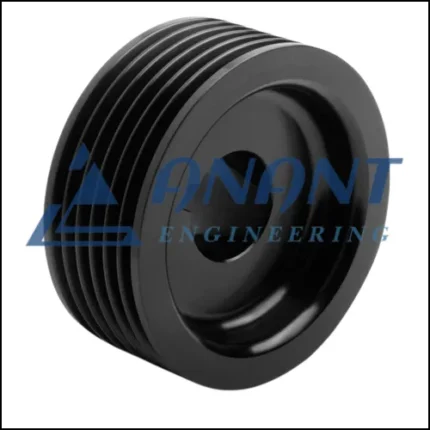

Flat Belt Pulley

Welcome to Anant Engineering, a trusted and leading manufacturer of high-quality flat belt pulleys in Mumbai, Maharashtra, India. Our commitment to excellence and precision engineering has made us a preferred choice for industries worldwide. We take pride in delivering flat belt pulleys that offer exceptional performance, reliability, and efficiency in power transmission.

The Importance of Flat Belt Pulley

Flat belt pulleys play a crucial role in various industrial applications, serving as a vital component in power transmission systems. These pulleys are designed to connect driving and driven components, facilitating the transfer of power from one component to another. By maintaining proper tension and alignment, flat belt pulleys minimize slippage, ensure efficient power transmission, and enhance overall system performance.

Flat-belt pulleys play a crucial role in various industrial applications, serving as a vital component in power transmission systems. These pulleys are designed to connect driving and driven components, facilitating the transfer of power from one component to another. By maintaining proper tension and alignment, flat-belt pulleys minimize slippage, ensure efficient power transmission, and enhance overall system performance.

At Anant Engineering, we fully understand the significance of pulleys in industrial operations. Our dedicated team of engineers and technicians work tirelessly to engineer pulleys that meet the highest standards of quality and performance. We combine advanced manufacturing techniques, cutting-edge technology, and stringent quality control measures to ensure that our flat belt pulleys exceed customer expectations.

Advantages of Our Flat Belt Pulleys

When you choose our flat-belt pulleys, you benefit from a range of advantages that make them the preferred choice for numerous applications. Here are some key advantages:

- High Torque Transmission: Our pulleys are designed to provide high torque transmission capabilities, making them ideal for heavy-duty machinery and demanding applications. Whether you’re operating metal rolling mills, paper machinery, cranes, dredgers, or rubber and plastic industries, our pulleys deliver efficient power transfer, ensuring smooth and reliable operation.

- Versatility: Our flat-belt pulleys offer versatility in accommodating varying speeds, making them suitable for a wide range of applications. From conveyors and elevators to compressors, fans, and blowers, our pulleys can handle diverse speed requirements, enabling optimal performance across different industries.

- Durability and Longevity: We prioritize durability and longevity in the design and manufacturing of our pulleys. Constructed from high-quality materials, our pulleys are built to withstand demanding environments and heavy loads. With precision engineering and robust construction, our pulleys offer exceptional longevity, minimizing maintenance requirements and reducing downtime.

Types of Flat Belt Pulleys Available at Anant Engineering

- Solid Flat-Belt Pulleys: Solid pulleys feature a single-piece construction, offering robustness and precise control in power transmission. They are suitable for applications that require high torque transmission and accurate speed control.

- Split Flat-Belt Pulleys: Split pulleys consist of two halves that can be separated, making installation and maintenance easier without the need to remove the belt. These pulleys offer convenience and flexibility, especially in applications where frequent belt changes or adjustments are necessary.

Factors to Consider When Choosing the Right Flat Belt Pulley

Selecting the right flat-belt pulley for your specific application requires careful consideration of various factors. Here are some key aspects to keep in mind:

- Belt Type and Size: Determine the specific type and size of the belt required for your application. This ensures compatibility between the belt and the flat-belt pulley, enabling optimal performance and efficient power transmission.

- Speed and Load Requirements: Evaluate the desired rotational speed and the load the pulley needs to handle. Consider the torque and power requirements of your machinery to ensure that the selected pulley can meet the demands of your application.

- Shaft Diameter and Keyway: Take into account the shaft diameter and keyway dimensions to ensure a proper fit between the pulley and the shaft. Proper alignment and secure connection are essential for reliable power transmission.

- Material Selection: Consider the operating environment and select a pulley material that can withstand the conditions effectively. Factors such as temperature, humidity, corrosive substances, and abrasive particles should be taken into account when choosing the appropriate material for your pulley.

Manufacturing Process of Flat Belt Pulleys

At Anant Engineering, we employ advanced manufacturing processes and techniques to ensure the production of high-quality flat belt pulleys. Our manufacturing process involves several stages, including precision machining, heat treatment, and strict quality control measures. We are best known as flat belt pulley manufacturers.

- Precision Machining: We utilize state-of-the-art machinery and equipment to precisely machine the pulley components. This ensures dimensional accuracy and smooth surface finish, contributing to optimal pulley performance.

- Heat Treatment: Our pulleys undergo heat treatment processes to enhance their mechanical properties, such as hardness and strength. Heat treatment ensures that the pulleys can withstand the stresses and loads encountered during operation, improving their durability and longevity.

- Quality Control: We have a dedicated quality control team that rigorously inspects and tests each flat belt pulley before it leaves our facility. We conduct various tests, including torque capacity tests, alignment tolerance checks, and durability assessments, to ensure that our pulleys meet the highest standards of quality and performance.

Quality Assurance and Testing

At Anant Engineering, we prioritize quality assurance and testing to deliver flat belt pulleys of the highest quality. We understand the critical role that pulleys play in industrial applications, and therefore, we subject our pulleys to rigorous inspection and testing processes.

- Torque Capacity Testing: We test our pulleys to ensure their ability to transmit the required torque without slipping or experiencing excessive wear. This test verifies the pulley’s performance under different loads and ensures reliable power transmission.

- Alignment Tolerance: Proper alignment between the pulley and the driving and driven components is crucial for efficient power transmission. We conduct alignment tolerance checks to ensure that our pulleys align correctly, minimizing the risk of slippage and maximizing power transfer efficiency.

- Durability Assessment: Our pulleys undergo durability tests to evaluate their performance under demanding conditions and continuous operation. These tests simulate real-world operating conditions, ensuring that our pulleys can withstand the challenges of industrial environments.

Reliable Performance

When it comes to industrial components, reliability is paramount. At Anant Engineering, we understand the critical role that flat belt pulleys play in your operations. That’s why we go the extra mile to ensure that our pulleys are meticulously engineered and manufactured to deliver consistent and dependable performance, even in demanding conditions. With our flat belt pulleys, you can have confidence in the smooth functioning of your machinery, resulting in increased productivity and reduced downtime.

Extensive Applications

Our flat belt pulleys find application in a wide range of industries and machinery types. Here are some industries where our pulleys excel:

- Metal Rolling Mills: Power transmission

- Paper Machinery: Efficiency.

- Cranes and Dredgers: Heavy-duty

- Rubber and Plastic Industries: Material handling

- Cement Plants: Reliability

- Conveyors and Elevators: Transportation

- Compressors, Fans, and Blowers: Dependability

or Visit: anantengineering.in