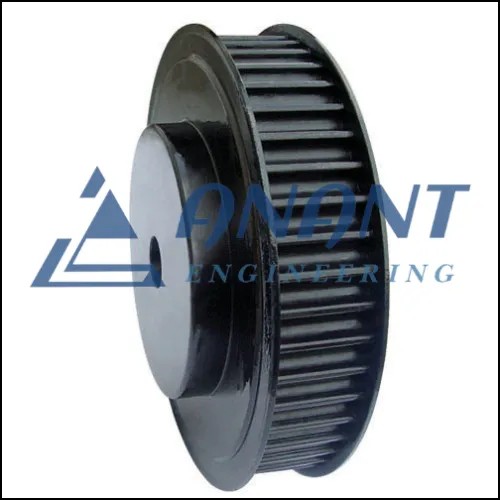

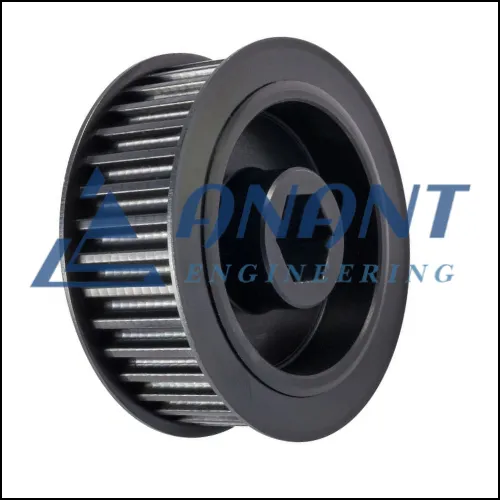

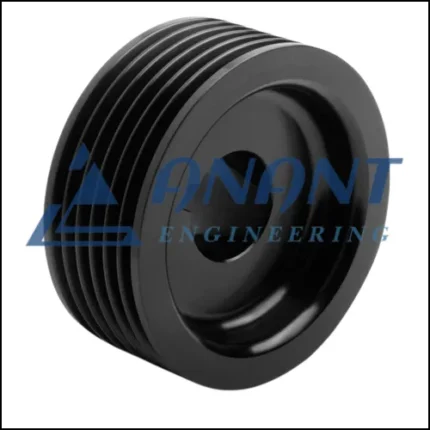

Timing Pulley

Welcome to Anant Engineering, a leading manufacturer of high-quality timing pulleys located in Mumbai, Maharashtra, India. Our meticulously designed pulleys are engineered to provide unparalleled flexibility and performance in power transmission. With precision engineering and superior craftsmanship, our timing pulleys ensure a secure and efficient connection between the driving and driven components, enabling precise timing and reliable power transfer.

The Importance of Timing-Pulleys

We play a crucial role in various industries, including manufacturing, automation, robotics, and more. They are key components in synchronous belt drive systems, allowing for accurate power transmission and synchronization between the driving and driven components. By maintaining precise timing, these pulleys ensure optimal performance and efficiency, minimizing the risk of slippage and enhancing the lifespan of machinery. At Anant Engineering, we understand the significance of pulleys in industrial applications, and our products are engineered to deliver exceptional performance.

Advantages of Our Timing-Pulleys

We offer several advantages that make them a preferred choice for many applications. Firstly, they provide accurate timing and synchronization, enabling precise movement and control in various machinery and automation systems. Additionally, our timing pulleys are designed to minimize backlash, ensuring smooth operation and reducing the risk of vibrations. Moreover, our pulleys are manufactured with precision to ensure optimal tooth engagement, enhancing power transmission efficiency.

Types of Timing Pulleys Available at Anant Engineering

We offer a wide range to suit diverse application requirements. Some common types include:

- XL Timing Pulleys: XL timing pulleys are designed for light to moderate load applications that require precise timing and synchronization.

- L Timing Pulleys: L timing pulleys are suitable for moderate to heavy load applications that demand accurate power transmission and durability.

Factors to Consider When Choosing the Right Timing Pulley

- Belt Type and Size: Determine the specific belt type and size required for your application to ensure compatibility with the pulley.

- Teeth Profile: Choose the teeth profile of this pulley based on the type of synchronous belt being used.

- Speed Ratio: Evaluate the desired speed ratio between the driving and driven components to achieve the required output speed.

- Load and Power Requirements: Consider the load and power requirements of your application to select pulleys that can handle the transmitted power effectively.

Manufacturing Process of Timing belt Pulley

At Anant Engineering, our manufacturing process for timing pulleys involves several steps and incorporates advanced techniques to produce high-quality and reliable products. Here is an expanded explanation of our process:

- Design and Planning: Our skilled engineers and designers work closely to develop the optimal design for timing pulleys based on customer requirements and industry standards. This includes determining the appropriate dimensions, tooth profile, and material selection for the pulleys.

- Material Selection: We carefully select high-quality materials that possess the necessary strength, durability, and wear resistance for timing pulleys. Common materials used in pulley manufacturing include aluminum, steel, and various types of plastics or composites.

- Precision Machining: We employ precision machining techniques such as turning, milling, or grinding to shape the pulley blanks according to the design specifications. This ensures accurate dimensions and a smooth surface finish.

- Tooth Profile Cutting: The tooth profile of the timing pulley is critical for efficient power transmission and accurate timing. We use specialized cutting tools or CNC machining to precisely cut the tooth profile into the pulley’s surface.

- Heat Treatment: To enhance the hardness and strength of the pulley, heat treatment is performed. This process involves subjecting the pulley to controlled heating and cooling cycles to achieve the desired material properties, such as increased hardness and improved wear resistance.

- Surface Finishing: We apply surface treatments or coatings to the timing pulleys to enhance their performance and protect against corrosion. Common surface finishing techniques include anodizing, plating, or applying protective coatings like powder coating.

- Quality Control: Stringent quality control measures are implemented throughout the manufacturing process to ensure that each timing pulley meets or exceeds industry standards. This includes dimensional inspections, tooth profile checks, and material testing to verify mechanical properties.

- Assembly and Packaging: Once the pulleys have undergone thorough quality control checks, they are assembled with other components, if required, such as flanges or bushings. The final pulleys are then carefully packaged to ensure safe transportation and delivery to customers.

- Continuous Improvement: We are committed to continuous improvement and invest in research and development to explore new materials, manufacturing techniques, and design enhancements. This allows us to stay at the forefront of timing pulley technology and offer the best solutions to our customers.

By employing advanced manufacturing techniques, using high-quality materials, and implementing rigorous quality control measures, we at Anant Engineering ensure that our timing pulleys deliver exceptional reliability, durability, and performance for various industrial applications.

Quality Assurance and Testing

We understand the critical role that these pulleys play in industrial applications, and therefore, we prioritize quality assurance and testing. At Anant Engineering, our timing pulleys undergo rigorous inspection and testing processes to guarantee their performance and reliability. We conduct tests for dimensional accuracy, tooth profile precision, and more to ensure that our pulleys meet the highest standards of quality.

Extensive Applications

- Automation and Robotics

- CNC Machinery

- Packaging Machinery

- Printing Machinery

- Textile Machinery

Kindly Connect with our team to get more details and suitability for your application.

or Visit: anantengineering.in